A ball screw drive (BSC) is a mechanism that converts the rotational motion of a stepper motor into the translational motion of a moving part. Used for carriage CNC machine or 3D printer. The processing of the ends of the ball screws are standardized places for supports that fix the screw from longitudinal movements.

Dimensions for ball screws 1204, 1604, 1605, 2004, 2005, 2504, 2505, 2506, 2508, 2510, 3204, 3205, 3206, 3208, 3210.

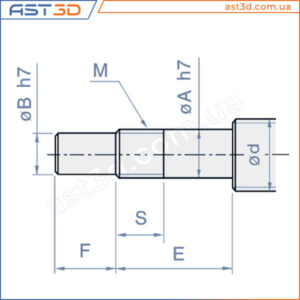

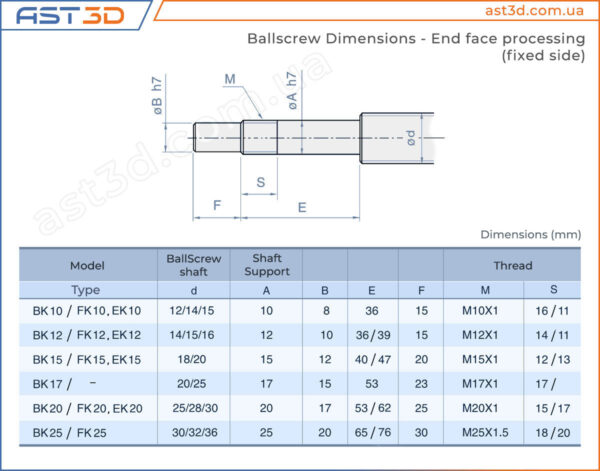

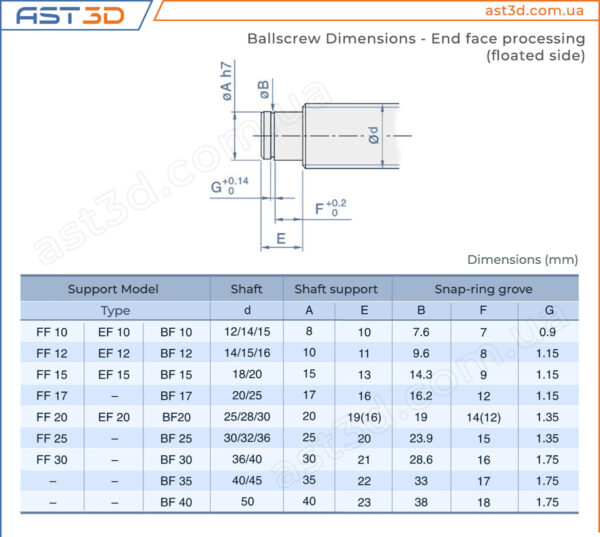

Processing the ends of the ball screws – places for supports

Dimensions and characteristics

(click to zoom)

(click to zoom)

The ball screw pair has a wide range of applications. This is due to the simplicity of the design and excellent mechanical characteristics. Ball screw is widely used in CNC milling machines. It is also used in 3D printers and laser engravers. In addition, the minimum friction and the small dimensions of the ball screw and nut allow it to be used in medical applications. Ball screws can be used in mechanical engineering and high-precision measuring instruments, such as 3D scanners.

Choose the right size for ball screws and specifications. Use AST3D reference materials, we will always be happy to help you.

AST3D supplies screws with standard processing as well as custom-made screws.